Manual transmission cars offer drivers complete control over their vehicle’s power and performance. Yet many new drivers feel intimidated by the clutch pedal and gear shifter combination.

We at floridadetscourse.com have developed comprehensive manual transmission car driving lessons that break down every technique into manageable steps. This guide covers everything from basic clutch operation to advanced hill starts and smooth gear transitions.

What Makes Manual Transmission Control Different

Manual transmission operation centers on three mechanical components that work together: the clutch pedal, gear shifter, and engine speed management. The clutch pedal connects your engine to the transmission. When you press the clutch fully down, you disconnect the engine from the wheels and allow gear changes without grinding. The friction point occurs roughly halfway up the pedal travel – this point marks where the clutch begins to engage and transfer power. Most drivers need 15-20 practice sessions to master this engagement point consistently.

Clutch Pedal Mechanics and Control Points

The clutch pedal operates through a hydraulic or cable system that controls the pressure plate. You must press the pedal completely to the floor during every gear change. Partial clutch depression causes slipping and premature wear. The engagement zone (or bite point) varies between vehicles but typically sits at 30-50% of pedal travel. New drivers often release the clutch too quickly, which causes stalling, or hold it partially engaged, which burns the clutch disc.

Gear Shifter Positioning and Movement Patterns

The standard H-pattern shifter requires specific directional pressure during shifts. First and second gears need leftward pressure against the shifter gate, while fifth and sixth gears require rightward pressure. Third and fourth gears sit in the center position. Never rest your hand on the shifter while driving – this habit causes premature wear to transmission synchronizers. The shifter should move smoothly between gates, and any resistance indicates potential transmission problems.

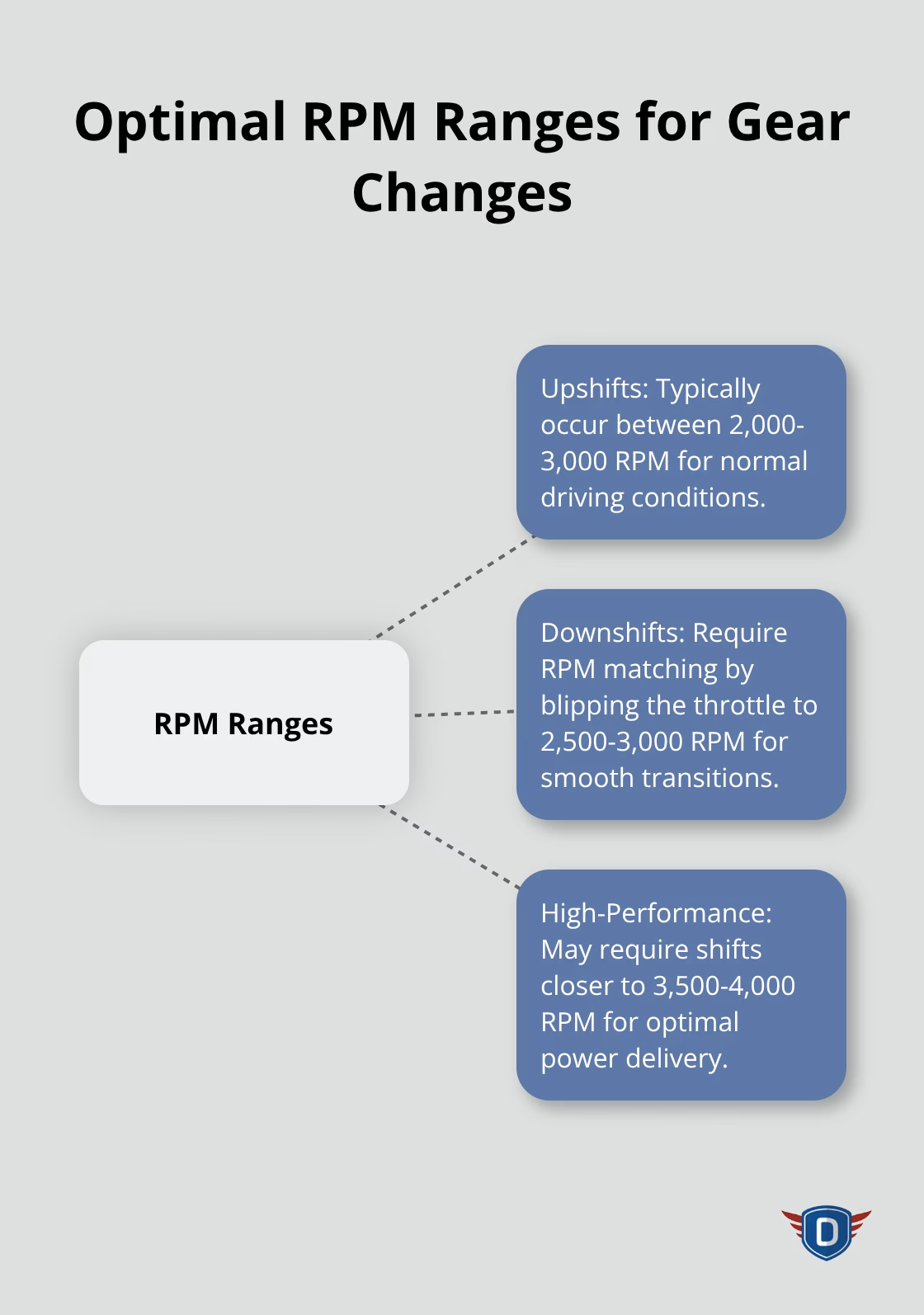

RPM Timing for Optimal Gear Changes

Engine speed coordination determines shift smoothness and transmission longevity. Upshifts typically occur between 2,000-3,000 RPM for normal conditions. Higher performance vehicles may require shifts closer to 3,500-4,000 RPM. Downshifts need RPM matching – you must blip the throttle to match engine speed and prevent transmission shock. Proper RPM management helps extend clutch life compared to aggressive patterns. Wrong gear selection at high speeds (called a money shift) can destroy engines instantly and transmission repairs can cost between $2,000-8,000.

These fundamental control principles form the foundation for every manual transmission technique. Next, we’ll explore how to apply these concepts through essential driving maneuvers.

How to Execute Core Manual Transmission Maneuvers

Manual transmission cars demand precise coordination between three pedals and the ignition system. Press the clutch pedal completely to the floor before you turn the key. The car will not start unless you fully depress the clutch – this safety feature prevents accidental movement. After you start the engine, keep the clutch pressed and shift into first gear. Apply light pressure to the gas pedal while you slowly release the clutch until you feel the engagement point. The car will begin to move forward as you continue to release the clutch and add more throttle. Most new drivers stall multiple times during their first practice session because they release the clutch too quickly or fail to coordinate the gas pedal properly.

Perfect Gear Transitions and Timing

Smooth shifts require you to match engine speed to road speed through proper RPM management. For upshifts, press the clutch fully, move the shifter to the next gear, then release the clutch while you maintain steady throttle pressure. You should complete the shift within one second to prevent synchronizer wear. Downshifts need additional throttle input – press the clutch, shift to a lower gear, blip the throttle to 2,500-3,000 RPM, then release the clutch. This rev-matching technique prevents transmission shock and extends component life. Skip-shifts from third to fifth gear during highway acceleration can improve fuel economy during certain driving conditions.

Master Hill Starts and Stop Control

Hill starts challenge new drivers because gravity pulls the car backward during clutch engagement. Use the handbrake method for steep slopes. Set the parking brake, press the clutch, shift to first gear, and apply throttle to 2,000 RPM. Slowly release the clutch until you feel the engagement point, then release the handbrake while you continue to ease off the clutch. The car should move forward without backward roll. For stops on inclines, downshift progressively rather than coast in neutral. Engine braking reduces brake pad wear and maintains better vehicle control. Practice hill starts in empty parking lots with artificial inclines before you attempt steep public roads.

These fundamental maneuvers form the building blocks of manual transmission competency. However, even experienced drivers make critical errors that can damage expensive transmission components and create dangerous situations on the road.

What Destroys Manual Transmissions Most

New drivers destroy manual transmission components through three predictable errors: improper clutch control, aggressive shifts, and poor RPM coordination. Stalls occur when drivers release the clutch too quickly without sufficient throttle input. The engine dies because the load exceeds available torque at idle RPM. Most stalls happen during first gear engagement when the clutch friction point engages too rapidly.

Practice sessions should focus on the exact clutch engagement point – typically 30-50% of pedal travel – where the engine RPM drops slightly and the car begins to move. Hold this position for two seconds before you release the clutch completely. This technique prevents 90% of stalls according to transmission specialists.

Clutch Component Damage and Prevention Methods

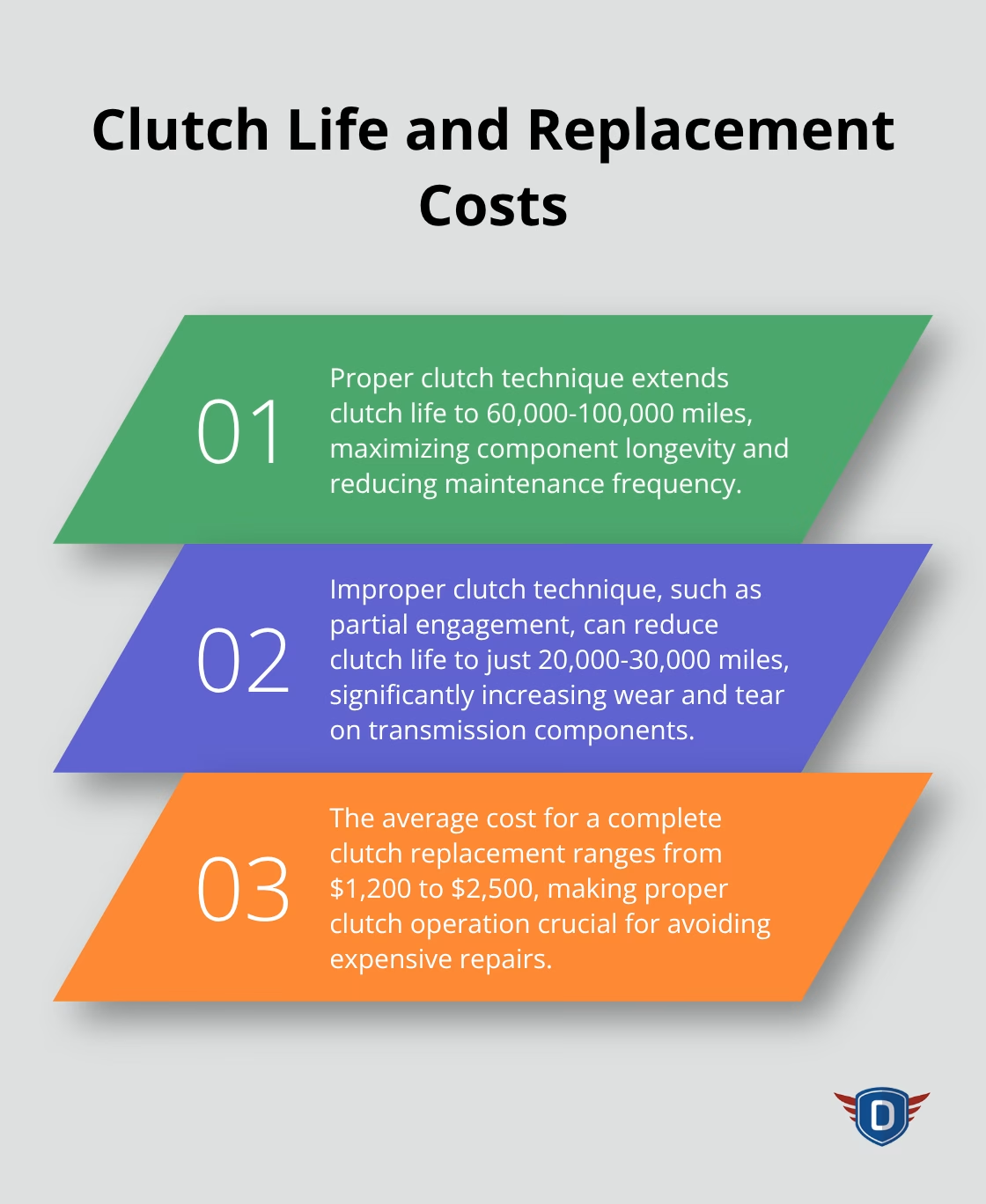

Partial clutch engagement destroys the friction disc within 20,000-30,000 miles compared to proper technique that extends life to 60,000-100,000 miles. Partial clutch engagement generates excessive heat that warps the pressure plate and burns the disc material. Never rest your left foot on the clutch pedal during normal operation.

At traffic lights, shift to neutral and release the clutch completely rather than hold it down. This practice prevents throw-out bearing failure and reduces driver fatigue. Clutch slip during hill starts should last no more than 3-5 seconds maximum. Extended slip during park maneuvers burns clutch material and creates expensive repair bills that average $1,200-2,500 for complete clutch replacement.

Transmission Synchronizer Protection

Grind noises during shifts indicate synchronizer damage from incomplete clutch depression or forced gear changes. Always press the clutch pedal to the floor before you move the shifter. Double-clutch technique helps older transmissions with worn synchronizers – press clutch, shift to neutral, release clutch briefly, press clutch again, then shift to desired gear.

Never force the shifter into gear if resistance occurs. Money shifts from high speed downshifts to first or second gear cause catastrophic engine damage. Speed-appropriate gear selection prevents over-rev conditions (first gear maximum 15 mph, second gear maximum 25 mph, third gear maximum 45 mph).

Final Thoughts

Manual transmission mastery requires consistent practice of three fundamental skills: precise clutch control at the engagement point, smooth RPM coordination during gear changes, and coordinated pedal operation during hill starts. Most drivers need 15-25 practice sessions to develop muscle memory for these techniques. Start your practice in empty parking lots where stalls and mistakes carry no consequences.

Focus on the clutch bite point repeatedly until you can engage first gear without the tachometer. Progress to gentle slopes for hill start practice, then advance to traffic situations only after you master basic coordination. Manual transmission cars provide direct mechanical connection between driver input and vehicle response (European markets demonstrate this preference with over 80% manual sales versus only 5% in the United States).

This control translates to better fuel economy, lower purchase prices, and enhanced engagement compared to automatic alternatives. We at floridadetscourse.com offer comprehensive manual transmission car driving lessons through certified instructors. Our structured approach helps drivers master these essential skills while they build confidence for real-world situations.